Trapezoidal Roof Double Layer Roll Forming Machine

Basic Info

Model No.: Customized

Product Description

Trapezoidal Roof Double Layer Roll Forming Machine

Product Description

Double roofing sheet Roll Forming Machine is also called Double Layer Roll Forming Machine or double layer machine.It is a kind of machine which have two production lines for the roof sheet, the upper layer is one line, and the under layer is another line.But the layers or two lines can not product at the same time. Compared with two sets single layer machine, it can save space,money,just with one electric control desk and one hydraulic station, so it is easy to do the maintenance for workers.

Photo of double layer machine for your reference:

Machine parameters

| No. | Main parameter | |

| 1 | Length of the main part | About 8500 х 1650 х 1500 mm |

| 2 | Weight of main part | About 6.5 t |

| 3 | Voltage | 380 V/50 HZ 3 Phase (as customer`s request) |

| 4 | Roller fixer | Middle plate welded |

| 5 | Frame | 350 H steel welded |

| 6 | Frame thickness | 20 mm |

| 7 | Drive mode | Chain |

| 8 | Material of rollers | 45# steel, surface hard chromium plating. |

| 9 | Material of shafts | 45# steel |

| 10 | Diameter of shafts | Φ 80 mm |

| 11 | Number of rollers | Up layer: 13 rollers Down layer: 15 rollers |

| 14 | Main power | 5.5 kw |

Usage of the roof sheet

The roof sheet made by the double layer machine can be widely used in Industrial and civil buildings, warehouse, special construction, large span steel structure house as the roof,

walls or interior and exterior decoration. Its thickness is from 0.3 mm to 0.8 mm,width can be 914 mm,1000 mm,1200 mm,1220 mm,1250 mm. This is the common and standard sizes.

You can also give your requests about the sizes , we can make and design the machine as per your special requests on sizes.

Packaging & Shipping

1. One 40ft container for loading one set machine with manual decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

1). Payment Term: 30% of the total contract value paid by T/T as down payment, the rest 70% of the total contract value to be paid by T/T after inspection by buyer in seller`s factory while before delivery.

2). Delivery Time: The seller guarantees the equipment will be ready for shipment within 30working days after receipt of deposit from the buyer. This machine is in stock now

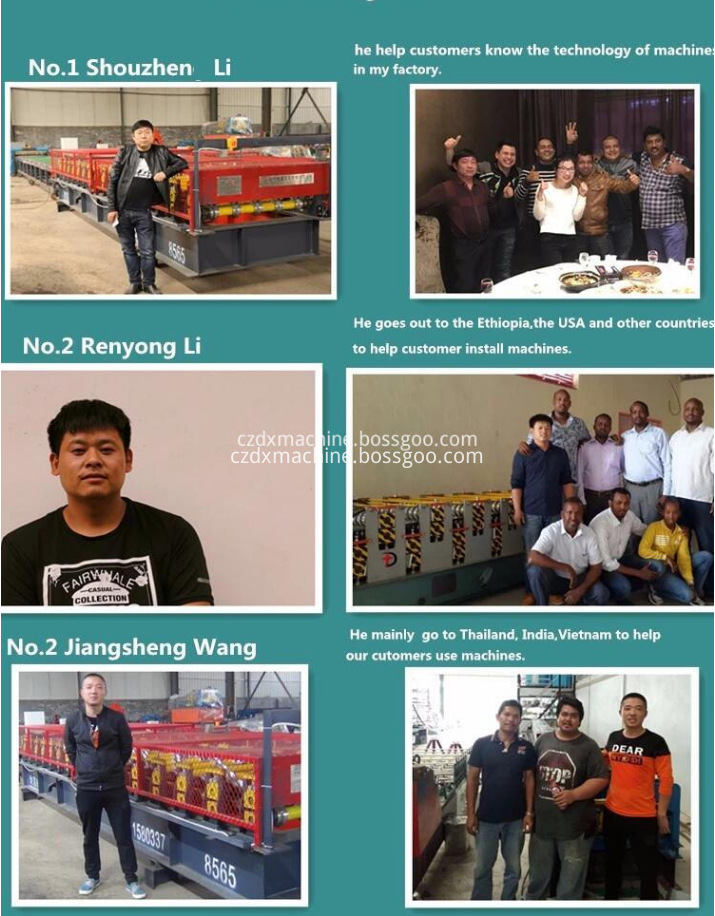

3). Service: We could send the technician to your country to fix the machine if you need.

4). Warranty: 12 months During the warranty, the replaceable parts are free, but the buyers need to pay for the shipping fee.We will also send one set CD and specification(Chinese and English) to you with the machine, they can teach you how to operate the machines.

Our company

![JRK%{9QS]~]SOIS4PNUKSMA JRK%{9QS]~]SOIS4PNUKSMA](http://i.glbin.com/product/8b/4f/15/75b7b9e021540014379559e7dd.png@watermark=2&color=I0ZGRkZGRg%3D%3D&type=ZHJvaWRzYW5zZmFsbGJhY2s%3D&size=21&p=5&t=80&text=Y3pkeG1hY2hpbmUuYm9zc2dvby5jb20%3D)

Welcome to our company!

If you have any question, please feel free contact me !

![FR]W4W`1~`BX8)M(9)RH7(7 FR]W4W`1~`BX8)M(9)RH7(7](http://i.glbin.com/product/1f/a3/7b/7f20c64a1d1aa7004448dc6839.jpg@watermark=2&color=I0ZGRkZGRg%3D%3D&type=ZHJvaWRzYW5zZmFsbGJhY2s%3D&size=21&p=5&t=80&text=Y3pkeG1hY2hpbmUuYm9zc2dvby5jb20%3D)

Product Categories : Double Deck Roll Forming Machine